Five things you must do when preparing turf mowers for spring

Spring is upon us. The long winter months are gone, and with the changing of the season, as turfcare professionals, we must ensure our mowers and equipment are prepared and set up for the busy time ahead.

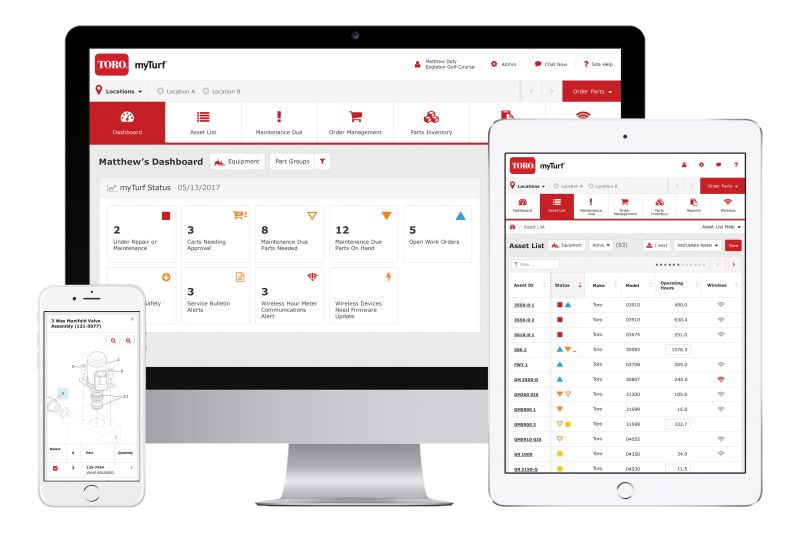

Though some machines will have been hibernating over winter, the vast majority – and particularly those used in the golf industry – will have been working, albeit with reduced hours but with harder working conditions. And with those hours of work, which can be tracked via an asset management tool like Toro’s myTurf Pro, comes the need for servicing and maintenance.

Regardless of your mower’s usage last season, it’s essential that you prepare it for a busy eight months of cutting during the spring and summer mowing season. As the idiom goes, ‘Fail to prepare, prepare to fail.’ To avoid any failures, then, here are five key checks and preparations you can make to ensure your lawn and greens mowers are ready for warmer weather, longer days, and that cool spring breeze.

1. Set your machine up for the conditions you’re in

You know it best – the golf course, the grounds, the public parks or buildings, the football stadium, or the rugby training pitch. It’s your turf and you know it inside out, and that’s why we always recommend turfcare professionals utilise their knowledge when setting machinery up at the start of spring.

A park in inner London is going to present different conditions to a golf course on the Isle of Skye – and that’s part of the beauty of our sector. But it also means there’s no one-size-fits-all, universal approach or set up for turf teams in different locations.

Be intentional about the coming weeks and months: What do you need to accomplish? What conditions will you and your equipment experience? What result do you need to deliver?

By thinking about these questions and answering them ahead of the new season, you’ll save time in the long run, avoiding unnecessary mistakes and damage to equipment.

My top tip:

-

Without a doubt, the single most important provision you can make for the mowing season ahead is setting your machine up for the conditions you’re in.

2. Inspect and clean every piece of machinery in your fleet

The winter season can be tough on equipment, even when it’s been stored properly. Begin by inspecting your mower from top to bottom, and look for any signs of wear and tear, especially on moving parts.

Though wear and tear is normal and par for the course in our sector, it must be acknowledged – ignoring something minor now could turn into something major tomorrow. While inspecting, pay special attention to rust and damage to the mower deck. Each specific model in your fleet should receive the same inspection standard.

It’s also important that you ensure all safety shields and guards are securely in place and functioning; a perfect cut isn’t a perfect cut if it’s not achieved safely.

Cleaning is equally important, and a clean machine will perform better in the months ahead. Dirt, debris, and old grass clippings can hide issues, cause corrosion, and hinder your machine’s performance. Use a blower to remove any loose debris; a pressure washer can then be used to eliminate any built-up dirt.

My top tip:

-

To prevent rust, make sure the mower can dry properly following cleaning.

3. Sharpen grass blades for a healthy, clean cut

The third maintenance task you need to complete to ensure your mower is ready for the new season is blade checking and sharpening.

If you want a clean, healthy, and attractive after-cut appearance, then you need sharp blades. If blades are dull, then this can lead to a jagged, uneven, and unsightly cut. But the consequences go beyond the aesthetics of your turf; a rough cut causes tears in turf leaves, which allows disease to enter.

In turn, torn leaves will show evidence of tip dieback before browning. Mowing with dull cutting units or blades will also put unnecessary stress on your turf and cause it to thin out. So for thicker, greener grass this spring, make sure your blades are sharp and ready for the job.

How to sharpen mower blades

-

With rotary blades, use hand grinders or machine grinders to sharpen blades. Ensure they are free from defects, nicks, or imperfections that can cause vibrations, and that all blades are balanced.

-

With flail blades, use Toro’s reel clamps so you can safely work on the shaft. Wear limits for your blades must be adhered to and fixings should be replaced and properly torqued for best results.

-

With cylinder mowers, use specialist equipment to sharpen cylinders and bed knives. Follow the operator manual for grind angles and depths. Once sharpened, set blades to the manufacturer’s recommendations.

If blades are too worn, have met wear limits (find these in the owner’s manual), or have otherwise been damaged, then you must replace them.

My top tip:

-

Always follow safety protocols, wearing appropriate PPE (even if the sun’s out), including goggles, ear defenders, and gloves, and carry out risk assessments, method statements, and safety checks where appropriate.

4. Change oil, air and fuel filters, and spark plugs to protect your investment

In any walk of life, it’s important to protect your investments. Just as you would put your car in for an annual service, regular maintenance is essential to secure the longevity and optimum performance of your turf mower.

Before the spring season starts, you should change the oil and replace the oil filter to keep your mower’s engine running smoothly. Fresh oil reduces friction and wear on engine components, providing an easier ride for your mower over the next eight months.

Air and fuel filters should also be checked and replaced if need be. With clean air filters, mower engines can ‘breathe’ correctly; whereas a new fuel filter will prevent impurities from entering the engine, which helps avoid any potential damage.

Spark plugs are crucial for the engine’s ignition process; they provide the spark that ignites the air/fuel mixture, and thereby powers the engine. A worn spark plug can cause your machine to run poorly… or not start at all.

My top tips:

-

Contact myself or the Reesink team to arrange a two-day turfcare mechanics training course, where you can learn about maintenance fundamentals, electrics, hydraulics, and more.

-

Training is available at your club, with your equipment, and with reference to your turf, or at our training centre in St Neots, Cambridgeshire.

5. Consider digital products to enhance and optimise operations

We recently wrote an article covering the five reasons why you should be using myTurf Pro as part of your asset management setup, so to avoid repeating ourselves, we’ll keep this one short.

Digital products, like Toro’s myTurf Pro, which is available through Reesink Turfcare, can offer course managers and groundskeepers an effective way of saving money by maximising outputs and avoiding costly repairs.

For myTurf Pro, an advanced tool that enables users to track and manage all their assets, no matter the brand, you’re effectively gaining an additional pair of eyes, without increasing your headcount. Spring is the season of new beginnings, so why not consider a new digital product to boost your performance?

My top tip:

-

To learn more about the digital products we offer, including how they could benefit your team, or ReeAssure, our range of maintenance service plans that will keep your fleet going all year round, call the team on 01480 226800.